Industrial tapes are incredibly versatile and play a day-to-day important role across various industrial sectors with numerous different types of tapes being available. These adhesive wonders enhance both efficiency and safety in industries ranging from manufacturing to construction. Their diverse applications, from securing heavy loads in logistics to insulating electrical components, make them indispensable in the industrial workplace.

The right choice of industrial tape caters to specific industry demands, ensuring optimal performance. Whether it is joining, sealing, or marking, industrial tapes are often the unsung heroes that streamline processes, prevent mishaps, and contribute significantly to a wide range of sectors’ success. Read on as we explore what are the five most popular different types of tapes for industrial use.

Types of tapes available

Industrial tapes are essential in many industries, including manufacturing, construction, and automotive. Because of their broad range, they are versatile and are utilised for a variety of applications. However, before picking an acceptable tape for use, it is important to confirm compatibility with industrial conditions. Industrial tapes are classified into several types, including double-sided, electrical, masking, and duct tape.

Choosing the correct tape for a certain application is critical, as the incorrect one may result in inadequate bonding, posing possible dangers.

1) Duct tape

Duct tape is made from fabric with a scrim backing and an ultra-strong adhesive. Among its qualities are:

- Durability – designed to last, duct tapes are exceptionally durable, and strongly resistant to “wear and tear”

- Strong adhesion – this tape sticks securely to a multitude of surfaces

- Tearable by hand – easy to tear and does not need cutting tools

- Temperature resistance – works effectively in a range of temperatures

- Versatility – use for a variety of purposes, e.g., bundling, repairs, sealing, etc.,

- Waterproof – this tape is especially waterproof in various environments

- Weather Resistance – can withstand various weather conditions

Table – Applications and Industries

Below we summarise a range of applications and industries where duct tape is commonly used:

| # | Application | Industries |

| 1 | Bundling and strapping | Shipping, warehousing |

| 2 | DIY projects | Home improvement, crafts |

| 3 | Emergency repairs | Outdoor and survival environments |

| 4 | Insulation | Electrical, automotive |

| 5 | Marking and labelling | Events, entertainment |

| 6 | Sealing and bonding | HVAC, plumbing, manufacturing |

| 7 | Temporary repairs | Construction, maintenance |

Versatility of use

Duct tapes perform well in industrial environments, providing solutions for rapid fixes, pipeline leak sealing, heavy cable bundling, and much more! Their adaptability, strong adhesion, and weather resistance make them important in keeping operations and safety running smoothly.

Strength and durability

Duct tape has a high capacity to withstand everyday wear and tear, this includes more difficult circumstances such as extreme temperatures and dampness. This is another reason this tape remains a trusted choice.

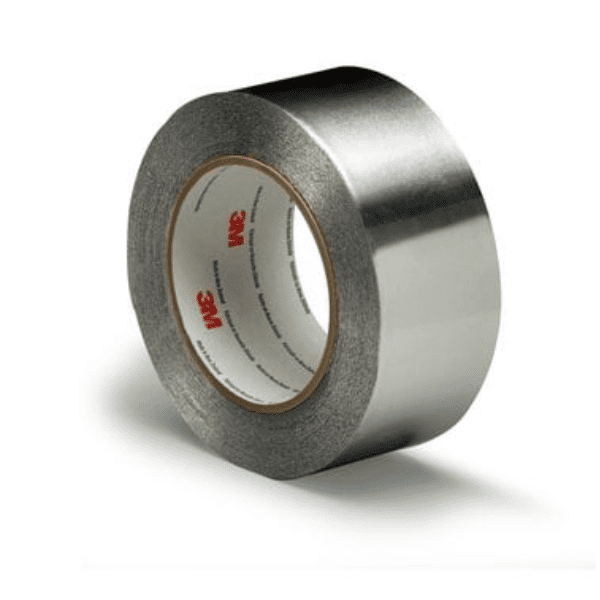

2) Electrical tape

As the name suggests, electrical tapes are used in a wide variety of electrical tasks. Electrical tapes provide an extra layer of security by creating a barrier between exposed electrical components and potential dangers.

Insulating properties

With superior electrical insulating qualities, these cables are in commonplace use far beyond electricians. Every business will have electrical insulation tape somewhere on the premises whether they know it or not! Choose electrical tape to withstand day-to-day challenges including high temperatures, humidity, and other environmental factors around electrical wires.

Electrical insulation is an invaluable ally

Standards and regulations compliance

There are standards and regulations in place in the UK for safety at work. Electrical tapes must comply with these standards for the safety of employees, customers, suppliers, visitors, etc., Top-quality electrical tape will provide reliable insulation and will defend against electrical shocks and short circuits.

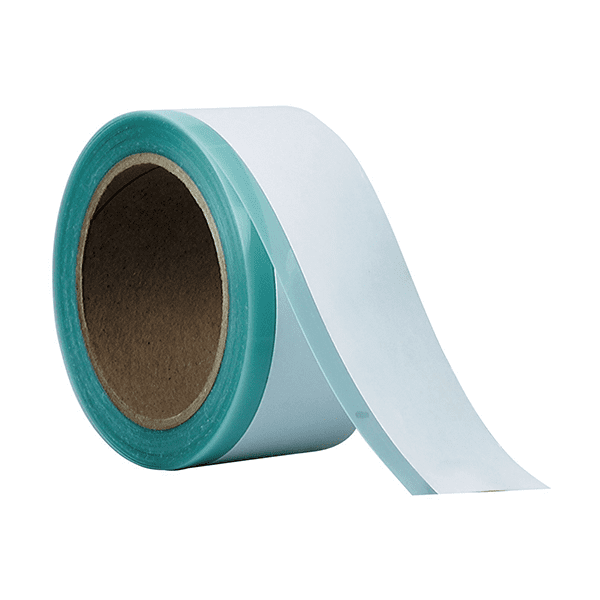

3) Packaging tape

Used extensively in mail services, shipping, and logistics choose packaging tape to ensure that your packages safely arrive at their destination.

Different types of packaging tape

We have summarised some of the different types of packaging tape in the table below:

| # | Type of tape | Unique features |

| 1 | Carton sealing tape | Used for sealing and securing cartons during shipping and storage |

| 2 | Filament tape | Reinforced tape with fibreglass strands for added strength and support |

| 3 | Masking tape | Versatile tape used for painting, holding, and bundling purposes |

| 4 | Gummed paper tape | Adhesive tape activated by moisture for secure sealing of packages |

| 5 | Duct tape | Strong, waterproof tape ideal for repairs and temporary fixes |

| 6 | Strapping tape | Heavy-duty tape for bundling and securing heavy objects |

| 7 | Double sided tape | Adhesive tape with adhesive coating on both sides for bonding materials |

This is an ideal type of packaging tape to use

Durability and reliability

Packaging tapes are engineered to withstand the demands of shipping and handling. This ensures that packages remain protected and intact. This quality minimises the risk of damage, loss, and costly product replacements for the small price of the tape!

Dependable sealing and bundling

Packaging tapes provide dependable sealing and bundling solutions. Whether it is sealing cartons, bundling products together, or securing fragile items, these tapes offer strong adhesion and peace of mind.

4) Double sided tape

Double sided tape serves a wide range of purposes and is employed for general mounting on numerous surface types. With adhesive layers on both sides, its primary function is to securely bond two surfaces, leaving no trace of visibility once applied.

This double sided tape is perfect for industrial use

Industrial uses

Some industrial uses of double-sided tapes include:

- Electronics – mounting and securing components in electronic devices and appliances

- Signage – attaching signs and graphics

- Construction – bonding panels and construction materials

- Textiles – joining fabrics and textiles

- Automotive – assembling automotive parts

Factors to consider

When selecting double sided tapes, several factors need to be considered, including:

- Ability to remove – removal properties, especially for temporary or repositionable applications

- Ease to apply – ease of use for efficient bonding

- Environmental tolerance – temperature resistance to withstand different environmental conditions

- Material compatibility – compatibility with the materials being joined to prevent damage or failure

- Strength and durability – to ensure a long-lasting bond

5) Masking tape

Masking tape is a thin, pressure-sensitive tape made of paper that is easily torn. It has a pressure-sensitive adhesive that is easily disengaged. Masking tape (sometimes called mounting tape or painter’s tape) comes in a variety of widths and is often used to mask off sections that need not be painted or varnished. Its characteristics also make it indispensable in a variety of other applications where precision and short-term adherence are required. Choose masking tape at DTC from leading suppliers including BAXT.

Choose masking tape for a range of “masking off” purposes

Important characteristics

Masking tapes have characteristics that make them ideal for precision tasks:

- Adhesive control – adjustable adhesion for varying levels of stickiness

- Clean removal – they can be removed without leaving sticky residues

- Compatibility – works with various paints and coatings

- Conformability – easily conforms to curved or uneven surfaces

- Sharp lines – they create crisp, well-defined lines

- Tear resistance – resistant to tearing during application

- UV resistance – suitable for outdoor use

Applications across industries

Masking tapes have applications in diverse industries including:

- Aerospace – precision masking in aircraft maintenance

- Automotive – ideal for detailing, pinstriping, and paint protection

- Construction – marking, labelling, and temporary surface protection

- DIY projects – crafting, home improvement, and creative endeavours

- Electronics – circuit board assembly and solder masking

- Marine – boat painting and surface protection

- Medical – securing tubing and devices during procedures

- Painting – precise edge masking for clean, professional paint jobs

- Renewable energy – solar panel assembly and installation

- Theatre and set design – creating stage props and backdrops

Precision in surface treatment

Masking tapes are renowned for their precision in surface treatment. Whether in professional painting or DIY projects, they ensure sharp, clean lines, protecting surfaces from unwanted paint or coatings and enhancing the quality of the final finish.

Benefits

Masking tapes enable accurate detailing, protect surfaces from overspray, and simplify the painting process. DIY enthusiasts also find them invaluable for projects requiring precision and clean edges, making masking tapes a versatile tool across various sectors.

Table summarising the different types of tapes available

| Tape Type | Primary Uses | Key Characteristics |

| Duct tape | Repairs, sealing, bundling | High strength, durability, and moisture resistance |

| Electrical tape | Electrical insulation, splicing | Dielectric strength, heat resistance, and flame retardant |

| Packaging tape | Carton sealing, bundling | Adhesion strength, durability, and weather resistance |

| Double sided tape | Bonding, mounting | Adhesive on both sides, and various adhesion strengths |

| Masking tape | Painting, surface protection | Easy removal, precision, and temperature resistance |

Concluding thoughts

Industrial tapes are versatile and provide an often underestimated but essential role across many industries. They enhance efficiency and safety in manufacturing, construction, and other sectors with tape choice being available, which cater to specific industry demands.

Five specific industrial tapes were focused on, these were:

- Duct tape – are durable, versatile, and suitable for various applications

- Electrical tape – offer insulation and safety in electrical work

- Packaging tape – ensure product protection and supply chain efficiency

- Double sided tape – provide permanent bonding solutions in various industries

- Masking tape – offer precision in painting and surface protection tasks

Contact DTC

If you require any information or assistance regarding industrial tapes (including exterior anti slip tape, hazard warning tape, industrial adhesive tape, and thermoplastic tape, which are not mentioned in this article), do not hesitate to contact us at DTC.

You can contact us in the following ways:

- Visit our contact page

- Call us at – 023 8025 1100

- Send us an email at – sales@dtc-uk.com