-

Manual Handling

Composite Work Trolley

-

Manual Handling

3-Level Workshop Trolley Heavy Duty

-

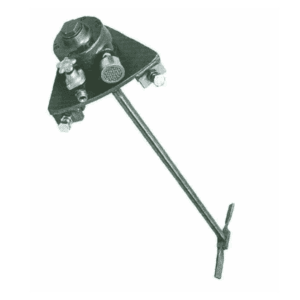

Fluid Handling

Air Powered Tank Mixer

-

Fluid Handling

Air Powered Drum Mixer

-

Fluid Handling

Heavy Duty Metal Plugless Drum Tap

-

Fluid Handling

Single IBC Bunded Spill Pallet

-

Fluid Handling

Water Hose Reel c/w 25m Hose

-

Fluid Handling

Measuring Jug – 2L

-

Fluid Handling

25L Metal Paint Pail & Lid

-

Fluid Handling

Barrel Bund

-

Manual Handling

Heavy Duty Platform Trolley

-

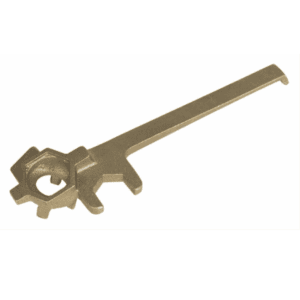

Fluid Handling

Drum Wrench