Maintaining a yacht’s pristine appearance is not merely about aesthetics. It is a crucial aspect of care that preserves the vessel’s value, functionality, and longevity. For seasoned industry professionals, the intricacies of yacht polishing are familiar territory. However, periodic reminders and fresh perspectives are always beneficial to ensure best practices are followed. Below, we look at expert strategies and considerations for effective yacht polishing.

Fibreglass vs Painted Yachts

Yachts are made of various materials, each requiring tailored maintenance. Fibreglass yachts feature a gel coat, and a protective resin layer that provides colour and gloss. Over time, exposure to harsh marine environments and UV rays causes the gel coat to oxidise, leaving it chalky and dull. Polishing helps restore the gel coat’s natural oils, removing surface imperfections and enhancing its shine.

Painted yachts, conversely, are coated with materials rich in emollients. While visually stunning, these surfaces are equally prone to fading and oxidation when exposed to sunlight and salt water. Polishing rejuvenates the paint by removing dead layers, restoring the oils, and reviving its depth and vibrancy.

Polishing in Maintenance

EPolishing is often misunderstood as a simple waxing procedure. In truth, polishing involves abrasion. This is a controlled process of removing imperfections, such as fine scratches, stains, and oxidation, to reveal a smoother, shinier surface. Done correctly, it revitalises a yacht’s gel coat or paint, setting the stage for the crucial next step: waxing

Waxing

After polishing, waxing provides a protective barrier against UV rays, salt, and contaminants. It seals the surface, preventing oxidation and prolonging the freshly restored finish. Waxing should be part of regular maintenance, ideally performed at least twice per season or more frequently for yachts exposed to harsh conditions.

(Image of BAXT W6 Double-Sided Lambswool Polishing Head)

Tools to Use

The tools and products used in yacht polishing can make or break the process. Industry-grade materials ensure efficiency, precision, and long-lasting results. Here is a quick rundown:

Polishing Tools: Orbital polishers are a staple, ensuring even pressure distribution and minimising the risk of surface damage. For tight corners or sensitive areas, manual polishing with microfibre cloths offers greater control.

Polishing Pastes and Compounds: Designed to remove oxidation and imperfections, these vary in abrasiveness. Professionals often start with a coarser compound for initial correction before transitioning to finer products for a flawless finish.

Protective Waxes: Marine-specific waxes provide superior UV resistance and water repellence. Always opt for formulations designed for the gel coat or marine paint to ensure compatibility.

Steps for Effective Yacht Polishing

Preparation: Begin with a thorough wash to remove salt, grime, and existing wax layers. A clean surface ensures polishing compounds work effectively without embedding dirt into the finish.

Inspection: Check the hull for damage, such as cracks or deep scratches. Address these issues before proceeding to avoid further deterioration.

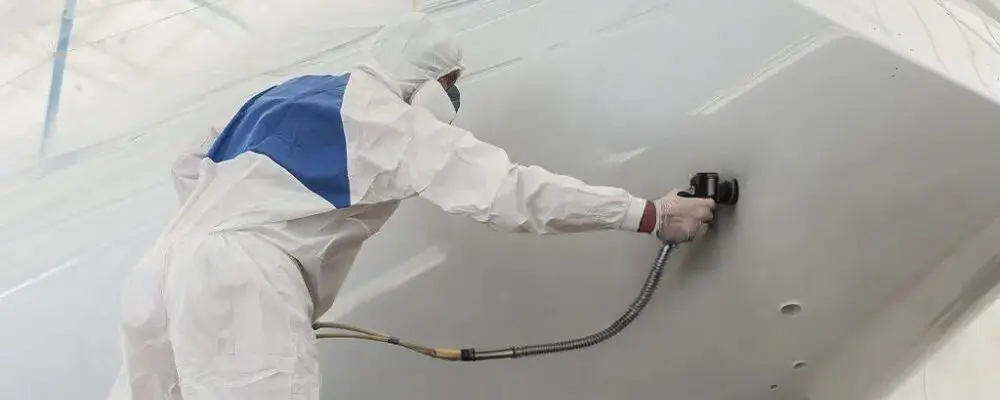

Polishing: Apply polishing compound in small sections, working in circular motions for even coverage. Orbital polishers with BAXT M100 can expedite the process, but manual techniques are indispensable for intricate areas.

Wax Application: After polishing, apply a thin, even layer of wax using a soft cloth or applicator pad. Let it set as per the product instructions before buffing to a high shine.

Final Touches: Use finishing sprays to enhance gloss and provide an extra layer of protection. Regular rinsing after outings and quick waxing between sessions can maintain the shine and extend the time between full polishes.

Frequency of Polishing

How often a yacht requires polishing depends on usage, exposure, and environmental factors. Charter yachts, which endure heavy use and constant exposure, benefit from polishing at least twice a year. This is usually done before and after the charter season. For private vessels, annual polishing combined with regular inspections and touch-ups suffices in most cases.

Professional vs DIY: Finding the Balance

While many yacht owners take pride in DIY maintenance, professional polishing offers unparalleled precision and durability. Professionals possess advanced tools and expertise, ensuring even application and minimal risk of damage. For heavily oxidised or damaged surfaces, professional intervention is often the most cost-effective choice.

Beyond Aesthetics

Polishing is more than cosmetic. It is an investment in your yacht’s long-term health and value. By committing to regular maintenance and adopting professional techniques, you will ensure your vessel remains not only a source of pride but also a reliable partner on the water.

-

BAXT M100 Gelcoat and Marine Compound – 1Lt£27.14 Incl. VAT£22.62 Excl. VAT

BAXT M100 Gelcoat and Marine Compound – 1Lt£27.14 Incl. VAT£22.62 Excl. VAT -

12V Cordless Polisher Kit 71mm – 3 Batteries£155.94 Incl. VAT£129.95 Excl. VAT

12V Cordless Polisher Kit 71mm – 3 Batteries£155.94 Incl. VAT£129.95 Excl. VAT -

BAXT B5 Polishing Waffle Foam (2)£19.90 Incl. VAT£16.58 Excl. VAT

BAXT B5 Polishing Waffle Foam (2)£19.90 Incl. VAT£16.58 Excl. VAT

To view more articles by DTC click here: Insights Archives | DTC (dtc-uk.com)