Whether working on a composite, wooden, ferrocement, or metal surface, achieving a flawless finish is fundamental for optimal performance and aesthetics. Filling and fairing play a key role in reducing water resistance and ensuring a craft’s performance is second to none. This essential yet labour-intensive process can make all the difference from hulls to underwater appendages like keels and rudders. Here, we look at the best practices and products that simplify the journey to perfection.

Why Filling and Fairing Matter

Smooth, fair surfaces on marine craft improve hydrodynamic efficiency and contribute to better handling and fuel economy. Nowhere is this more important than on underwater surfaces, where even the smallest imperfections can significantly impact performance and reduce the skin friction drag. Filling and fairing ensure a seamless finish that maximises functionality and appearance, making it a vital process for professionals and DIY enthusiasts.

The Tools of the Trade: Key Products for Success

Epoxy Resin Systems

Epoxy-based fillers are the gold standard for marine applications. Compared to polyester resin systems, epoxy offers:

- Superior Water Resistance: Essential for long-lasting results.

- Minimal Shrinkage: Ensures durability and stability.

- Enhanced Adhesion and Strength: Ideal for demanding marine environments.

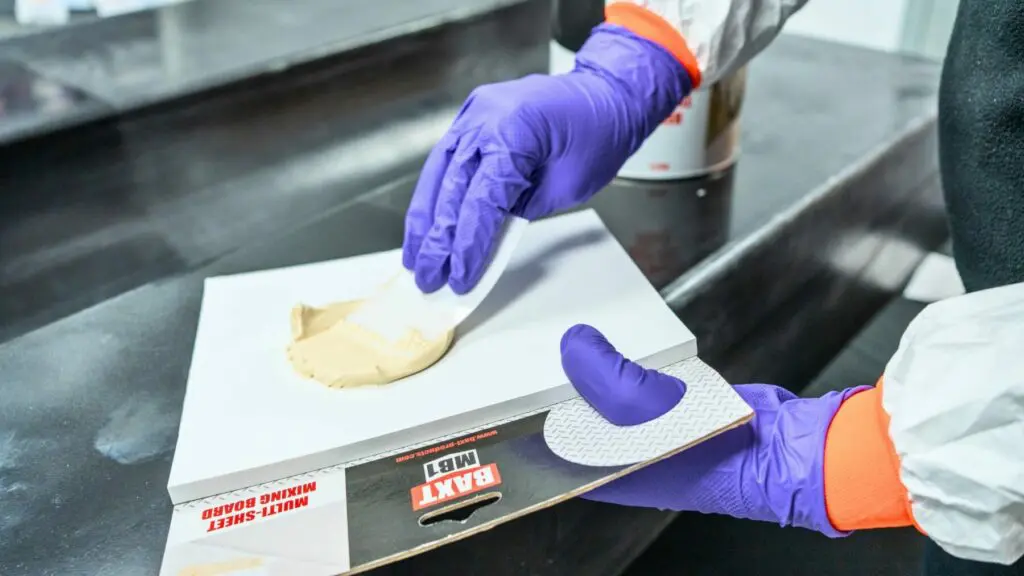

Professionals often favour the “recipe” method, mixing liquid epoxy resin with low-density filler powders. This approach allows the customisation of filler consistency for specific applications, offering flexibility and control.

Filler Ingredients

Hollow sphere fillers, such as microspheres, reduce weight while ensuring ease of application and sanding. These lightweight fillers displace resin to create a foam-like consistency, allowing for smoother finishes. Key types include:

- Phenolic Microballoons: Lightweight and easy to sand.

- Glass Bubbles: Ideal for structural applications.

However, achieving the perfect mix is crucial. Overloading with filler powder can result in a pasty texture and compromised adhesion.

Preparation Is Everything

The success of filling and fairing lies in thorough preparation. Different substrates require tailored approaches:

- Wood: Pre-coat with unfilled epoxy resin to enhance adhesion.

- Polyester GRP: Sand surfaces and solvent wipe for a strong key.

- Metal: Sandblast or prime with epoxy-based primers for optimal results.

- Ferrocement: Ensure reinforcement isn’t exposed and clean thoroughly before application.

Filling and Fairing Techniques

Overall Fairing

For large surfaces, such as hulls, start with thin layers of filler applied using a flexible applicator. Use tools like plastic fairing battens for an even spread. Employ techniques such as notched application to minimise filler waste and sanding effort. Once cured, sand high spots and fill low areas with a contrasting tinted mix to ensure precision.

Localised Fairing

For smaller areas like screw holes or voids, apply a stiffer filler mix using a spatula or straight edge. Colloidal silica can be added to improve non-sag properties, particularly on vertical surfaces.

Refining the Finish

Preliminary Fairing

Use tools such as sanding boards or mechanical sanders to remove excess filler and achieve a smooth surface. Coarser grades of abrasive paper are recommended during the early stages.

Fine Fairing and Finishing

High-build coatings, like SP Hibuild 302, are ideal for intermediate stages. These solvent-based products fill minor imperfections and sanding marks while minimising shrinkage. Alternate white and grey coats to identify high and low spots, then sand to achieve a flawless surface ready for paint application.

Your Path to Excellence

From resin systems to filler powders and high-build coatings, the right products and techniques ensure filling and fairing are efficient and effective. By mastering these processes, you’ll not only enhance your craft’s performance but also achieve a finish that’s smooth, fair, and built to last. Whether you’re working on a personal project or a professional endeavour, this guide provides the tools and insights to deliver exceptional results.

-

10.8V Cordless 150mm Dual Action Sander£123.54 Incl. VAT£102.95 Excl. VAT

10.8V Cordless 150mm Dual Action Sander£123.54 Incl. VAT£102.95 Excl. VAT -

BAXT CARBONfil Black Polyester Filler – 1kg£43.01 Incl. VAT£35.84 Excl. VAT

BAXT CARBONfil Black Polyester Filler – 1kg£43.01 Incl. VAT£35.84 Excl. VAT -

BAXT CARBONite Sanding Discs 150mm (50)From £29.90 Incl. VATFrom £24.92 Excl. VATRated 5.00 out of 5 based on 1 customer rating

BAXT CARBONite Sanding Discs 150mm (50)From £29.90 Incl. VATFrom £24.92 Excl. VATRated 5.00 out of 5 based on 1 customer rating

To view more articles by DTC click here: Insights Archives | DTC (dtc-uk.com)