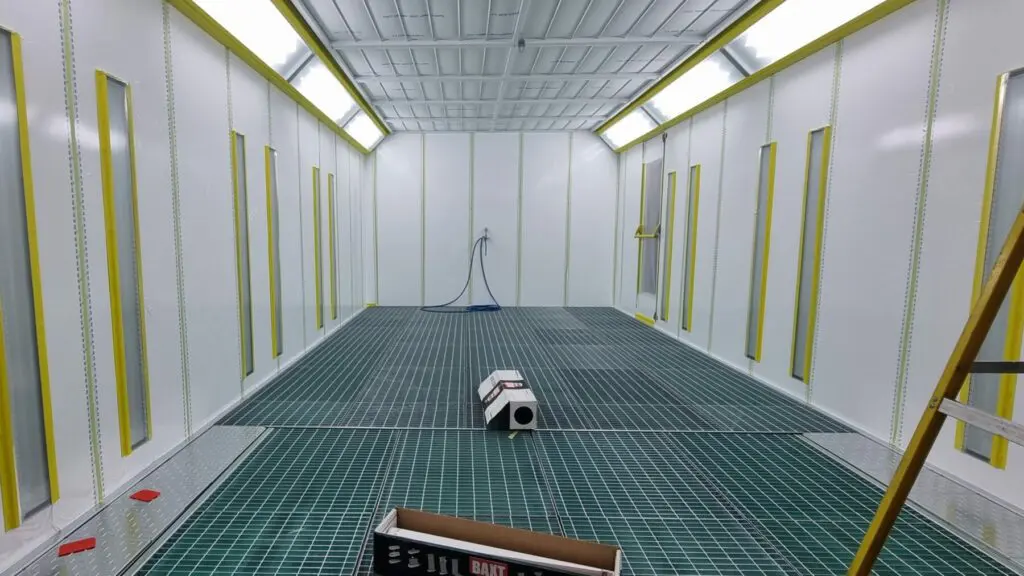

Whether you’re spraying cars, boats, aeroplane parts or joinery items, a well-maintained paint spray booth is vital for getting the perfect finish without suffering from inclusions or defects, as well as being a safe and pleasant space to work.

As the year comes to an end, it’s the perfect time of year to do a complete overhaul, making sure your booth is as safe and efficient as it can be throughout the year.

Do a Deep Clean of your Paint Spray Booth

Remove overspray build-up from walls, ceilings, floors, and doors. Deep clean with approved cleaning products and tools to prevent contamination and maintain a clean, pristine finish.

Strip out and replace Booth Coatings

If you have a booth coating on the walls or floor, now’s the time to get all this removed, and then replaced. Consider using a product like BAXT WP10 for the ultimate protection that lasts 5 times longer than a standard booth coating. Cover the lights with a clear coating like WP10 Clear, and cover the floor with a suitable product, for example FP10 Floor Coating.

For an in-depth look at the best type of booth coating, have a look at this article: What is the Best Spray Booth Paint Coating, and for a case study, you can read about how a specialist car refinisher upgraded their booth using BAXT WP10 here.

Wet backed Paint Spray Booths

Clean the contaminated water according the to manufacturer’s instructions or get a specialist company to do this for you.

Inspect and replace Filters

Inspect intake, exhaust, and air heater filters and replace as required. Ideally replace the extract filters every 50-70 jobs, or when the air flow falls below the required level as measure by a manometer. Make sure the filters completely cover the intake and extraction areas.

Check Doors and Seals

Adjust and lubricate hinges, clean glass, and inspect seals. Re-caulk door frames, internal seals and internal joints. NOTE: ensure that any lubricant or caulk is completely silicone-free and compatible with a paint spraying environment.

Inspect Heaters and Burners

Inspect burners annually with professional assistance.

Check and clean Exhaust System

Grease motor bearings with an approved product, and clean fans, dampers, and ductwork. Dirty blades on a fan will lead to vibration which will ultimately destroy the bearings leading to an expensive repair.

Structural Integrity

Inspect any screws and fixings in your paint spray booth and replace where necessary. The vibrations in a booth can cause fixings to fail and come loose, leading to an inefficient and noisy booth.

Fire Safety

Ensure the fire extinguishing system is professionally inspected.

Organise!

Consider investing in equipment to create a better and tidier booth:

- Spray booth magnetic boxes or spraygun cabinets

- Gun holders

- Solvent recyclers

- Gun cleaners

- Panel stands or turntables

By investing time into cleaning and maintaining your booth, not only will you extend its working life, but you’ll also have a safer, cleaner environment to spray in leading to less costly defects and reworks.

-

BAXT WP10 5-Layer Spray Booth Wall Protector£538.80 Incl. VAT£449.00 Excl. VAT

BAXT WP10 5-Layer Spray Booth Wall Protector£538.80 Incl. VAT£449.00 Excl. VAT -

Rotating Spray Table£237.60 Incl. VAT£198.00 Excl. VAT

Rotating Spray Table£237.60 Incl. VAT£198.00 Excl. VAT -

Spraybooth Filters 1m x 20mFrom £96.00 Incl. VATFrom £80.00 Excl. VAT

Spraybooth Filters 1m x 20mFrom £96.00 Incl. VATFrom £80.00 Excl. VAT